Reviewing 25 Years of Monitoring Results at AMPP EXPO ITALY

Long-Term Performance Of Galvanic Anodes For Steel Reinforced Concrete : George Sergi, Peter McClo…

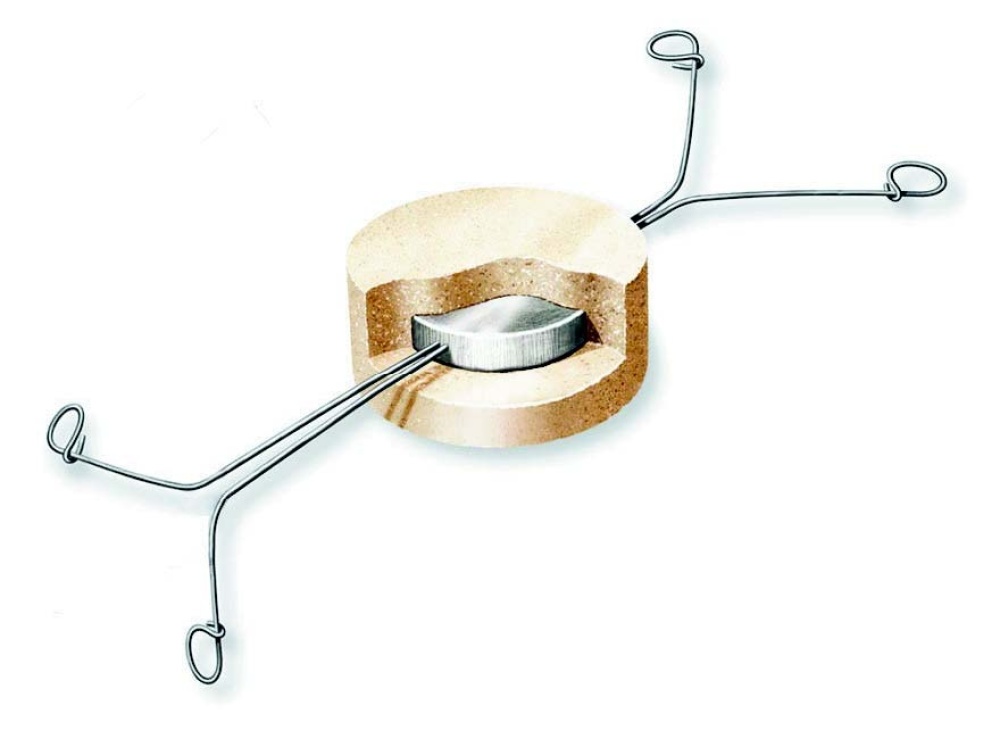

The Original Galvanic Anode for Reinforced Concrete Repair launched by Fosroc Corrosion Solutions

Vector secures the Galvashield® manufacturing license from Fosroc Corrosion Solutions and opens a manufacturing plant in Winnipeg, Canada.

Introduced for global protection and higher steel density applications

With a higher output and longer lasting performance

Moved to a larger dedicated manufacturing location on Otter Street

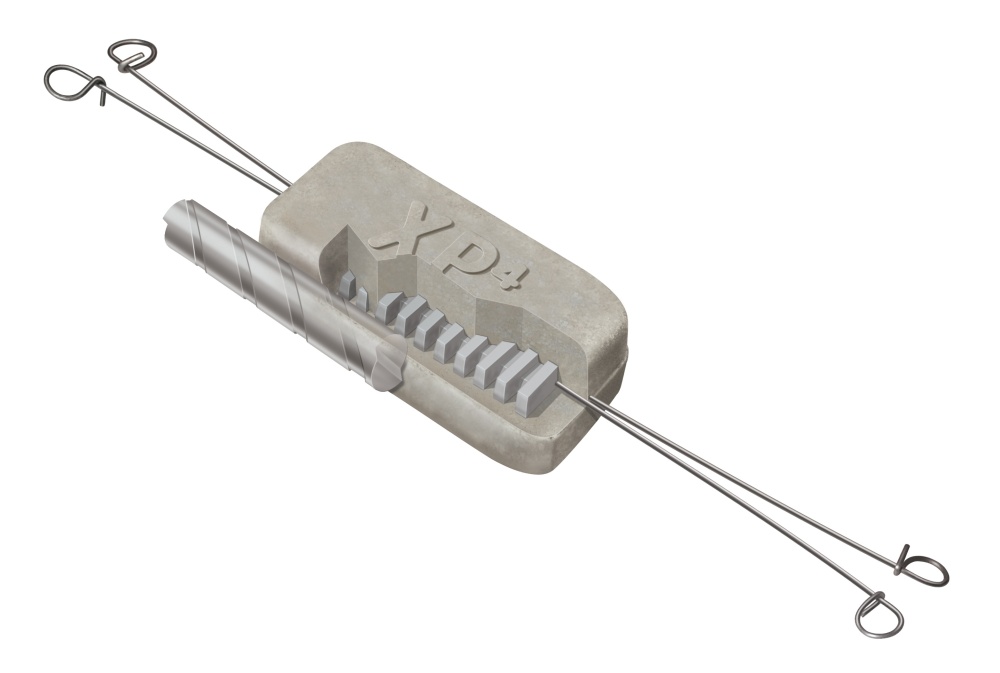

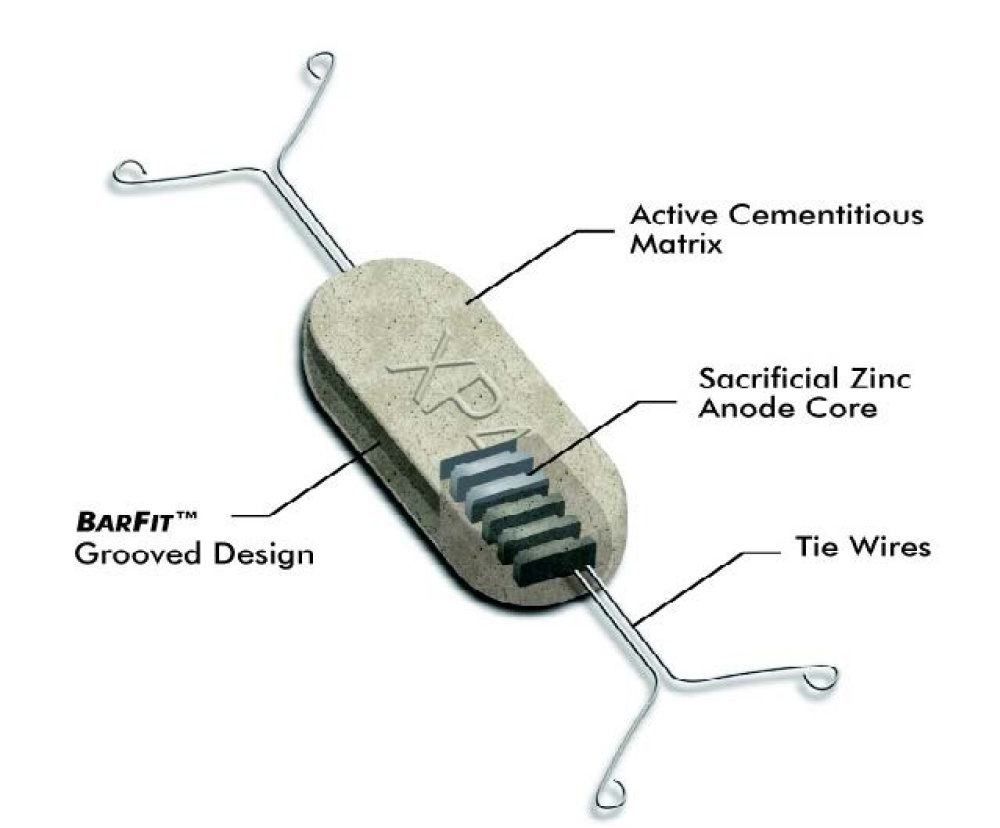

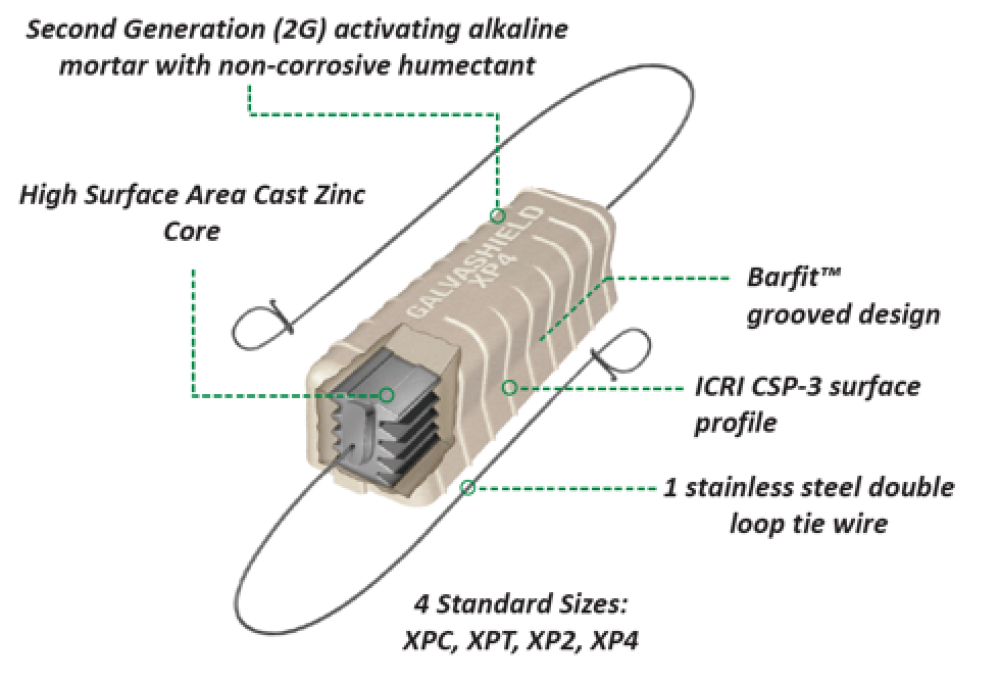

Galvashield® XP2 & XP4 are introduced for meeting corrosion control protection criteria and greater overall performance. First inclusion of Bar-Fit™ design

Vector acquires the original Galvashield R&D team and establishes a R&D Centre in Birmingham, United Kingdom

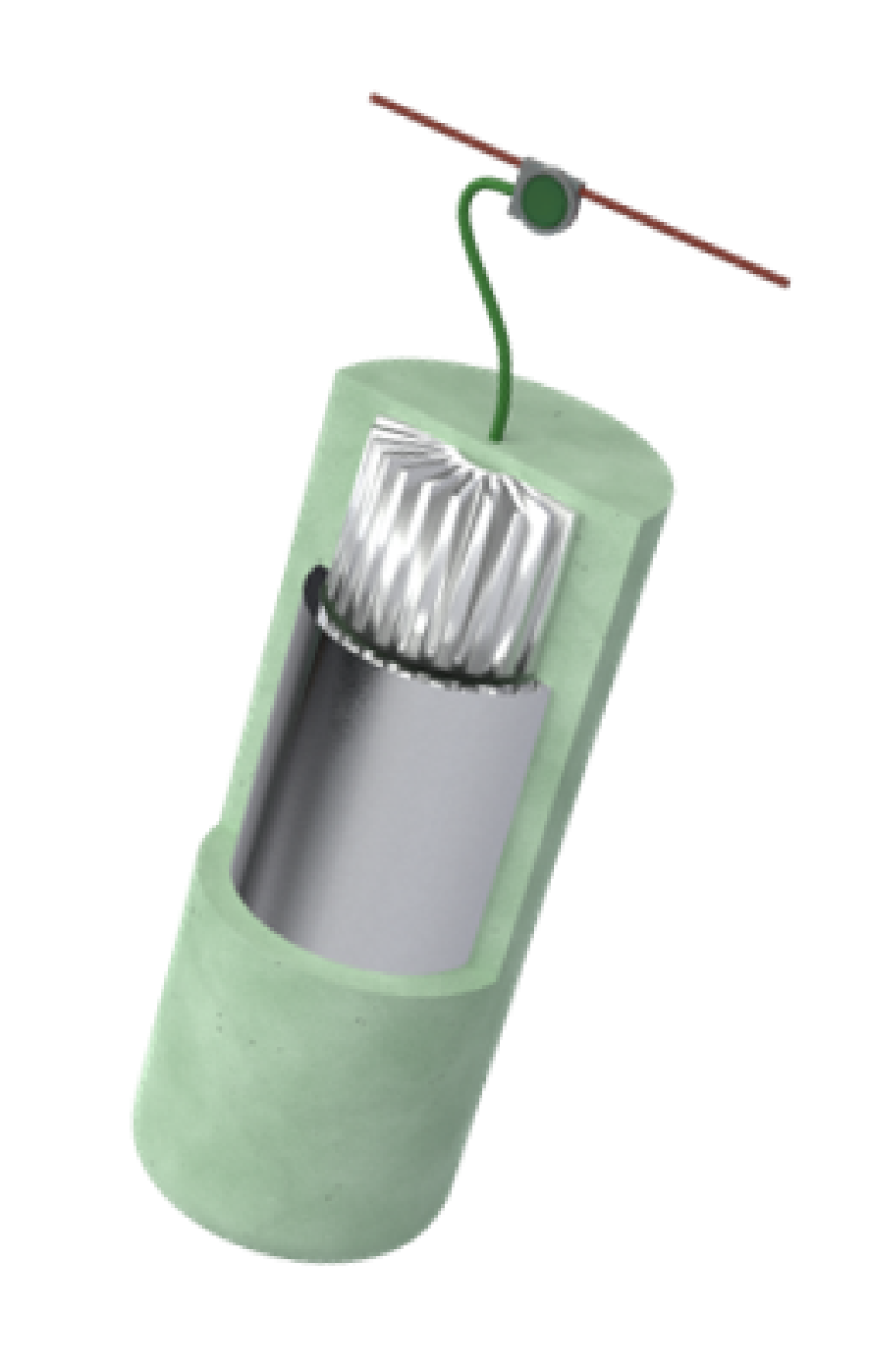

Introduced to be installed into new structures to provide corrosion prevention to reinforcing steel

Invention of Second Generation (2G) technology activating alkaline mortar

For lower budget or short-term protection requirement projects

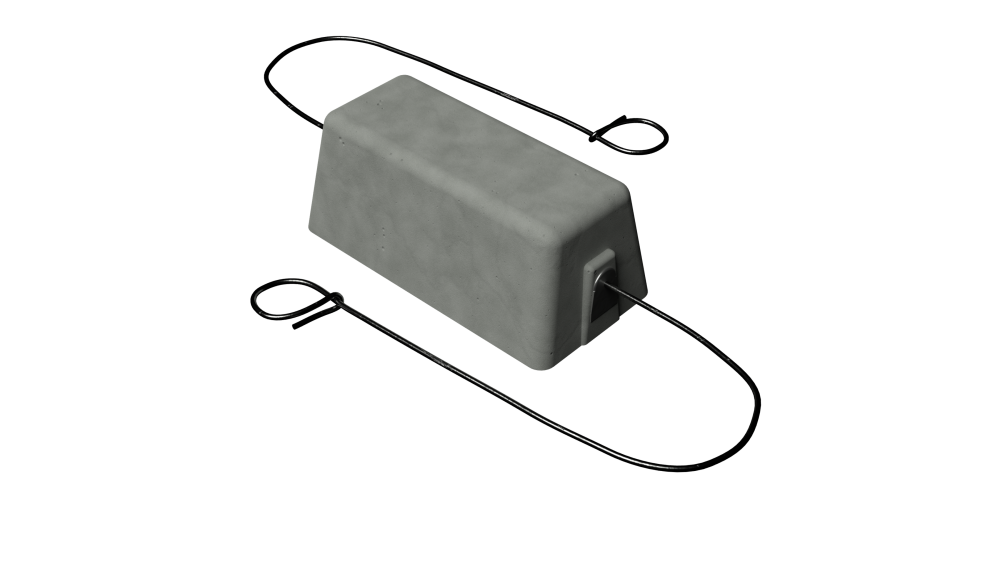

Introduced with bare zinc anodes placed inside a wicking fabric to extend zinc activation for protection above the tidal zone

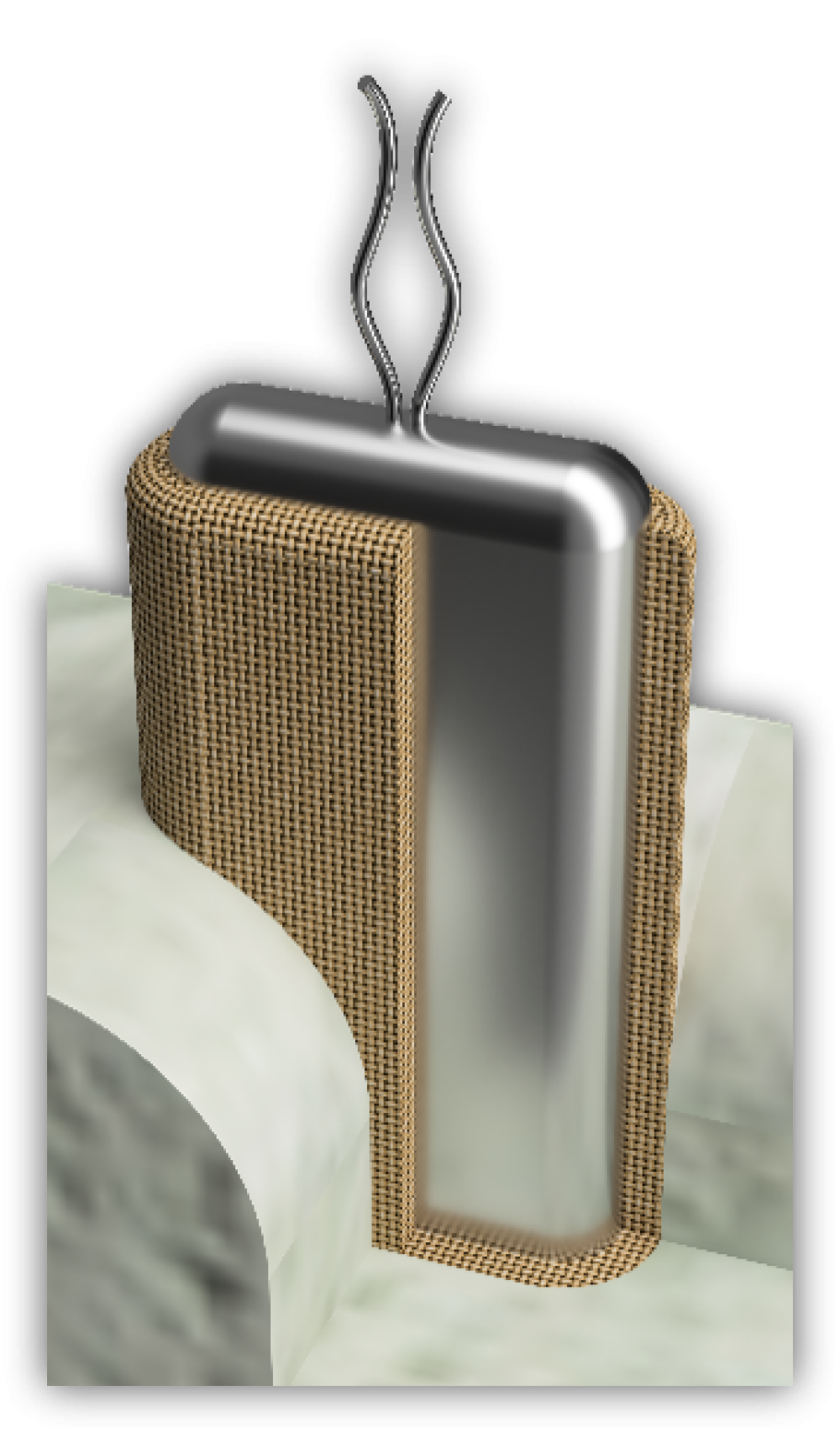

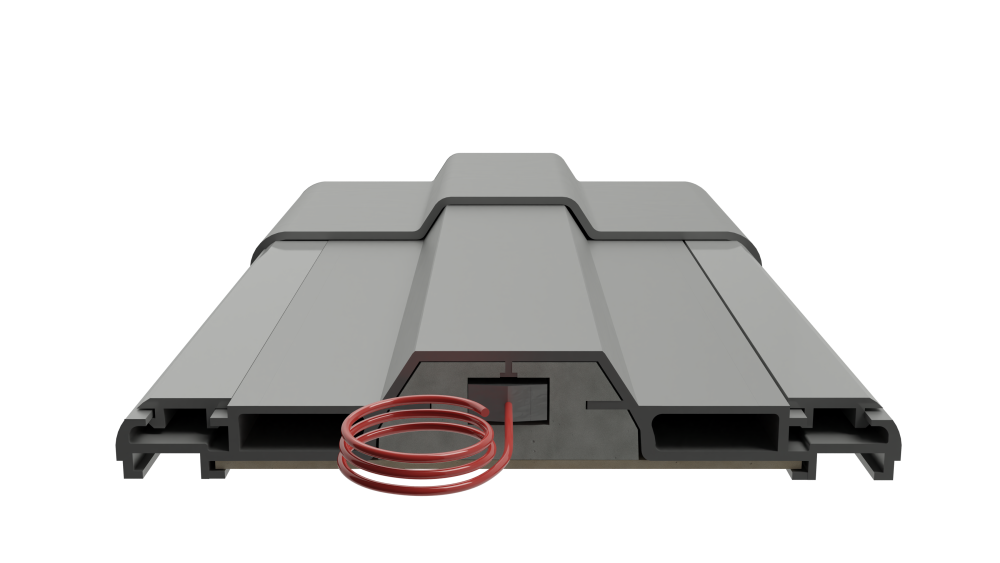

Combining the power of impressed current cathodic protection (ICCP) with the maintenance-free performance of galvanic anodes

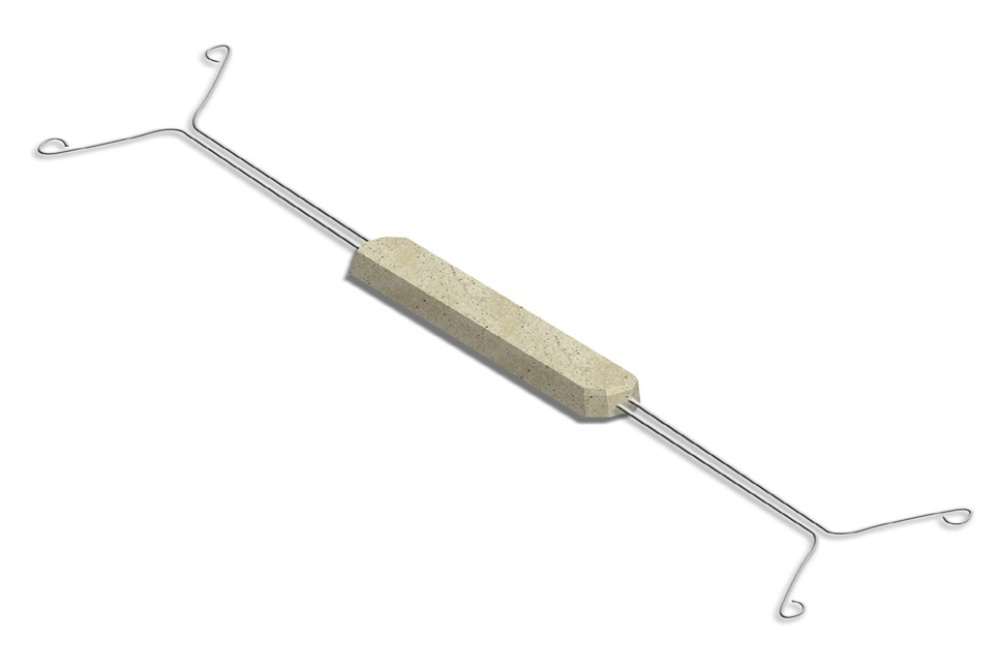

Galvashield® XP anodes are redesigned to be thinner and use the One & Done™ single stainless-steel wire to make them faster and easier to install

Expanded manufacturing to the USA to keep up with increasing demand

Introduced to meet performance requirements in extreme environments and high-temperature climates

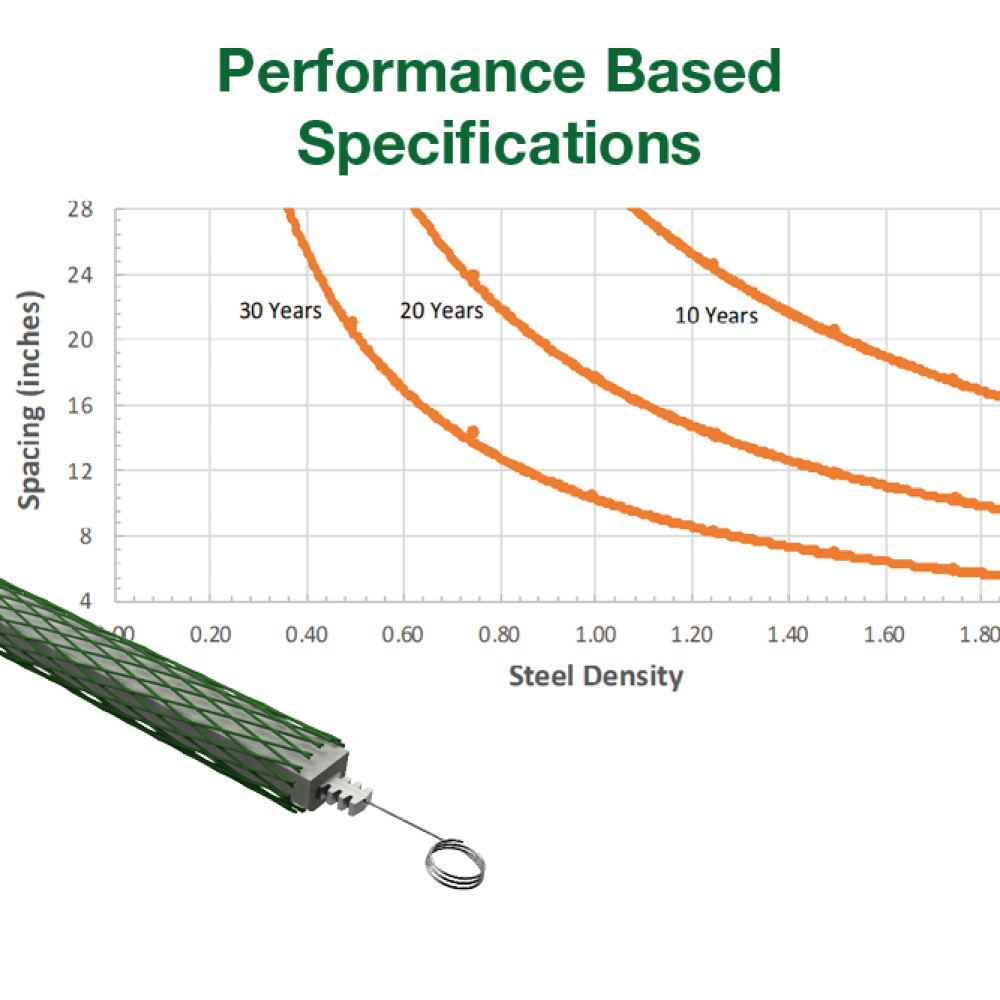

Introduction of a new design process that takes into account end of life performance, anode aging terms & environmental temperature.

Introduced to offer a surface mounted application of our DAS technology.

Expanded manufacturing to Indonesia to keep up with international demand.

Long-Term Performance Of Galvanic Anodes For Steel Reinforced Concrete : George Sergi, Peter McClo…

We are thrilled to announce that Vector Corrosion Technologies has been honored with the prestigious…

Our Nick Drews, Business Development Manager for the Mid-West United States region, has been awarded…