Galvashield® XP

Galvashield® XP Product Line

Galvashield® XP anode series, the original embedded galvanic anode for concrete repair, are used to mitigate ring anode corrosion or the halo effect when repairing reinforced concrete. Designed for optimum performance and ease of installation, the alkali-activated (Type 1A) anodes are comprised of high purity zinc cast around a steel tie wire with an enhanced formulated cement-based mortar with an internal pH of 14 or greater that keeps the zinc active over the life of the anode.

Galvashield XP anodes are available in 5 different sizes to fit any repair and provide a range of spacing options. The Galvashield XP anode is quickly and easily installed along the interface between new and existing concrete and tied to the exposed rebar using the One-and-Done™ single wire connection. Once installed, the zinc anode corrodes preferentially to protect the adjacent reinforcing steel. For anode system design details, refer to the technical data sheet.

Features and Benefits

- Proven technology: Galvashield® is the original embedded galvanic anode with over a 20-year track record.

- Long lasting: minimum 20 year anode service life when using standard design tables; reduces the need for future repairs.

- Independent testing: indicates concrete repair service life can be extended by more than 400%.

- Type 1A anode: alkali-activated to maintain activity of zinc; meets building code requirements that prohibit intentionally added constituents that are corrosive to reinforcement within repair area.

- One-and-Done™: connection innovative single wire connection can be installed up to 2x faster than the traditional two wire connection, saving 50% on installation labor cost.

- Cast zinc core: provides high anode utilization and a secure long-term connection between the zinc and the integral lead wire.

- BarFit™ design: grooved edges on Galvashield® XP2, XP4 and XPX anodes assist with secure anode placement.

- Integral steel connection wires: provides dependable steel-to-steel contact with no intermediate materials such as galvanizing that may compromise the long-term electrical connection.

- Economical: provides localized protection where it is needed the most, at the interface between the repair and the remaining contaminated concrete.

- Versatile: can be used for both conventionally reinforced and prestressed or post-tensioned concrete.

- Low maintenance: requires no external power source or system monitoring.

- ICRI CSP-3 (Concrete Surface Profile): raised ridges provide increased surface profile to promote mechanical bond with repair mortars and concrete.

Anode Type

1 - Installed in Concrete Repairs

2 - Installed in Drilled Holes in Sound Concrete

A - Alkali-activated using High pH

H - Halide-activated using Corrosive Salts

Repair Material Properties

For optimum performance, use Galvashield® Embedding Mortar to provide an ionically conductive path to the substrate.

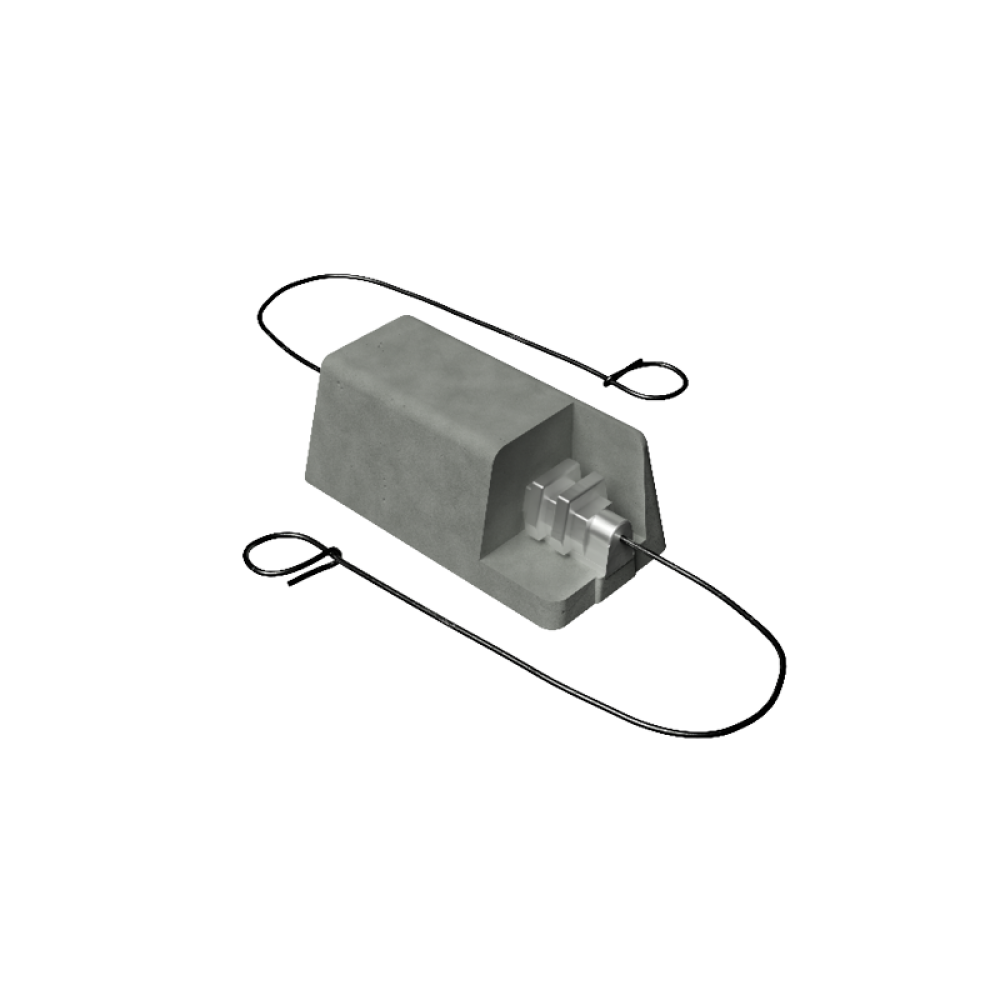

XP Compact

Nominal Dimensions

25 x 31 x 64 mm

(1 x 1.25 x 2.5 in.)

Zinc Mass

40 g

XPT

Nominal Dimensions

24 x 28 x 100 mm

(1 x 1.13 x 4 in.)

Zinc Mass

60 g

XP2

Nominal Dimensions

32 x 34 x 100 mm

(1.25 x 1.34 x 4 in.)

Zinc Mass

100 g

XP4

Nominal Dimensions

33 x 35 x 130 mm

(1.3 x 1.38 x 5.12 in.)

Zinc Mass

160 g

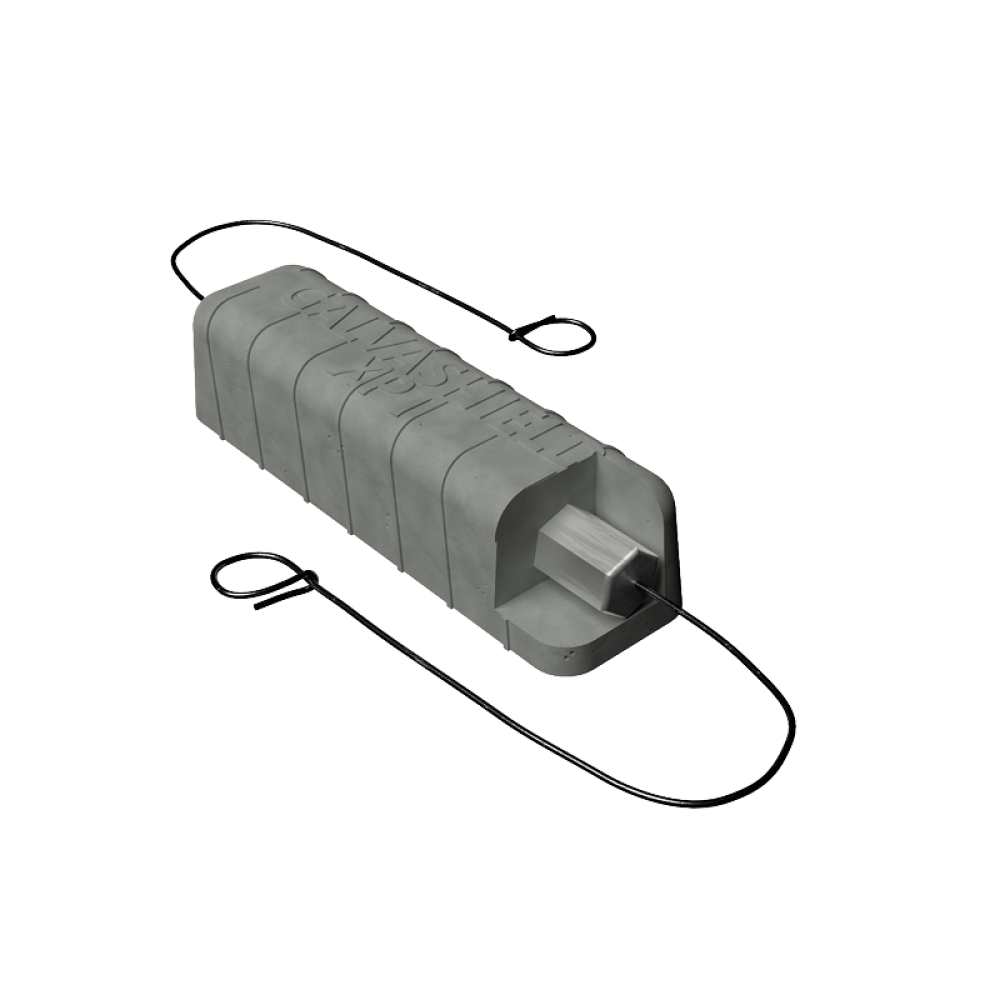

XPX

Nominal Dimensions

33 x 35 x 170 mm

(1.3 x 1.38 x 6.69 in.)

Zinc Mass

330 g

What is the X-Series?

Our X-Series of products ensure you get the high performance and long-term protection you need in any environment. Cathodic protection system designers should utilize Galvashield XPX if your structure sees average annual temperatures above 15°C or 60°F or is exposed to high levels of chlorides. To learn more about the X-Factor, read our blog post here.

Installation

Watch the following Galvashield® XPT step-by-step installation video. For Galvashield® XP Compact, XP2, and XP4 installation videos please visit our YouTube channel. Written installation instructions are also available below.

Applications

- Mitigates ring anode corrosion (halo effect) in concrete repairs

- Bridge deck repairs, expansion joint repairs, widenings and other structure modifications

- Parking deck, beam or column repairs, slab replacements and other interfaces between new and existing concrete

- Repairs to wharf slabs, beams, piles and pile caps

- Repair of pre-stressed and post-tensioned concrete

- Protects reinforcing steel in chloride contaminated or carbonated concrete

Technical Documents

Select a document to download product information. For CAD drawings in DWG format please Contact Us.

Technical Data Sheet

Installation Instructions

Project Examples

See how this product was used in successful projects.

Market Segments

This product has been used to solve corrosion problems across these markets.