USPS Mail Sorting Facility

The facility is equipped with state-of-the-art sorting machines and equipment, which can handle millions of pieces of mail each day. The sorting process at the facility is highly automated, with mail being sorted by destination zip code and routed to the appropriate mail carrier for delivery.

The Problem

The United States Postal Service building in Indianapolis, Indiana, had a unique situation. The exterior employee parking ramp was situated over a portion of the mail sorting facility.

Over time, chloride-contaminated water from de-icing salt application passed through the deteriorating asphalt overlay on the parking ramp. The corrosive salts penetrated the concrete deck causing reinforcing steel corrosion, concrete delaminations and spalling. Of particular concern was the high corrosion risk where full-depth cracks allowed localized high concentrations of chlorides to collect around both the top and bottom mat of reinforcing steel. A false deck was put in place to capture loose concrete and protect the workers and equipment in the sorting facility below.

Our Solution

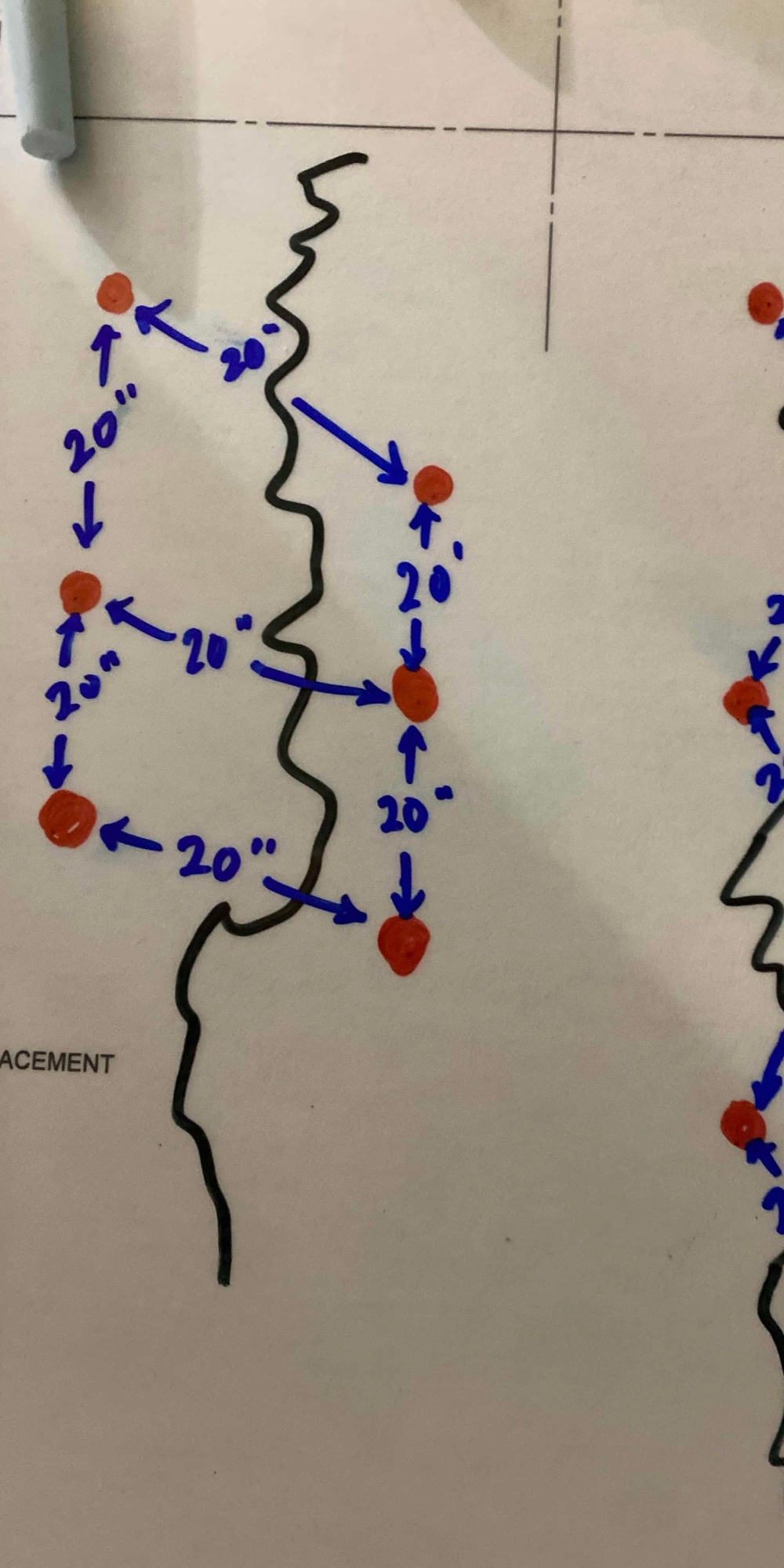

The consultant specified the removal of the existing asphalt overlay and partial and full-depth concrete repairs. To address the high corrosion risk / active corrosion around the full-depth cracks, the consultant specified Galvashield® Fusion T2 two-stage anodes to be proactively installed. These unique anodes produce a high level of internally generated impressed current in the first phase to passivate active corrosion and then autonomously switches to a galvanic maintenance current. The anodes were installed on both sides of the cracks at a spacing of 20 inches (500mm).

The Result

The combination of concrete repairs, waterproofing and installation of targeted cathodic protection to address remaining active corrosion sites is a holistic approach that will significantly enhance the safety, reduce maintenance and extend the service life of this important facility. The anodes are typically designed to provide a service life of up to or greater than 30 years, thus providing a long-term solution to the localized corrosion problem.

Technology Used

These innovative products and technologies were used on this project.