Potash Mine Foundation

Potash mines are a highly corrosive environment due to their high chloride level exposure and high temperatures. Because of this aggressive corrosion environment, reinforced concrete members within potash mines will corrode early in their service life if propper protection is not in place. In this case, new potash mine foundation bases had to be built, as the old bases were past the point of repair. The new foundation bases, which support a silo, would be exposed to the same conditions as the original including both fresh and brined water.

The Problem

Based on the foundation’s corrosive exposure and earlier experience, concrete reinforced with black steel rebar would be expected to corrode early in its service life. This owner also considered using epoxy-coated steel or stainless steel rebar in the new foundations, but when designing to achieve 30+ years of service life, the owners understood that extra corrosion protection would be needed and opted to use embedded galvanic anodes.

Our Solution

Embedded anodes were selected as a more flexible solution to economically and confidently meet the desired service life without adding delays to the construction schedule.

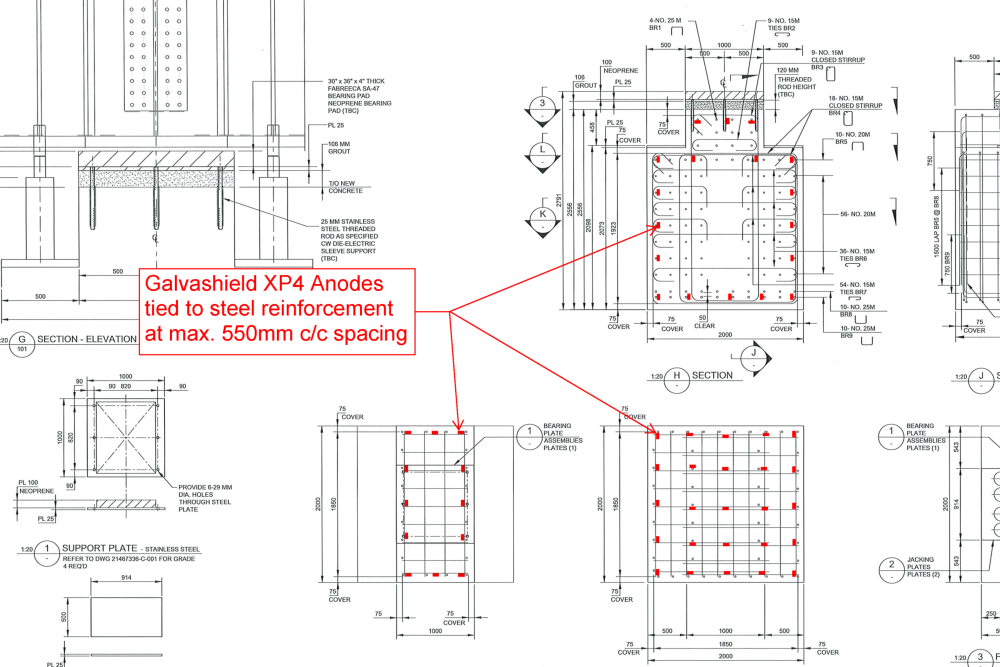

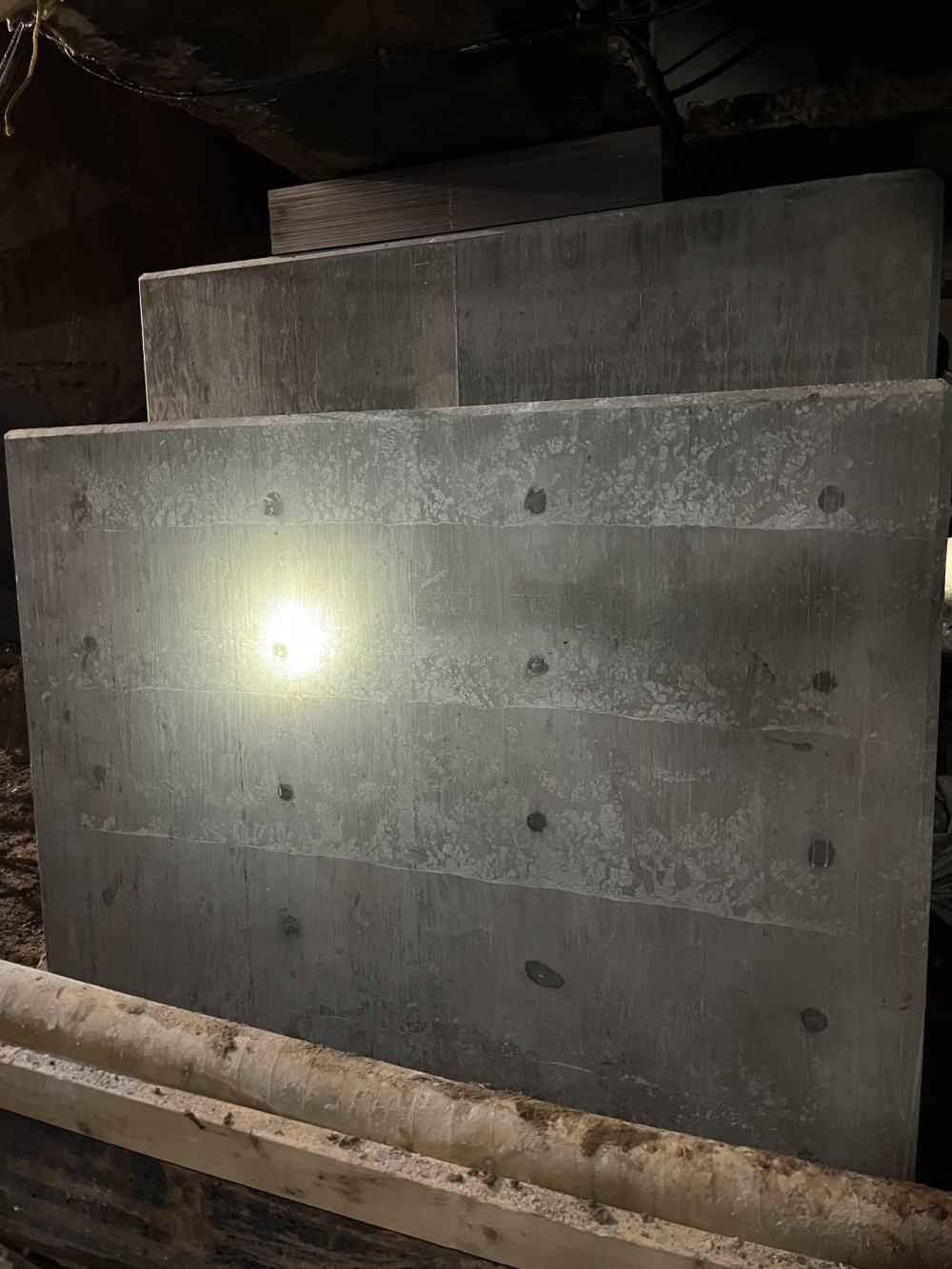

Galvashield® XP4 alkali-activated embedded galvanic anodes were installed in a grid on the surface of the new foundations to protect the black bar and achieve the desired service life.

The Result

The owner benefited from this solution with time and cost savings. Anodes and black bar had less lead time than stainless steel or epoxy coated bar on this project while also being less costly than stainless steel rebar.

The client was also able to tailor the service life of their steel to match that of the concrete, as the concrete's service life is expected to be shorter than what can be achieved for steel with the proper corrosion protection system in this environment. This resulted in additional cost savings for the owner.

Technology Used

These innovative products and technologies were used on this project.