Post-Tech® Drying & Regreasing

Post-Tech® Cable Drying

Once the Post-Tech® Corrosion Evaluation has determined the level of corrosion risk, a corrosion mitigation strategy can be put into place using the Post-Tech® Cable Drying and Grease Injection systems to protect and preserve the post-tensioned structure at a fraction of the cost of other repair methods.

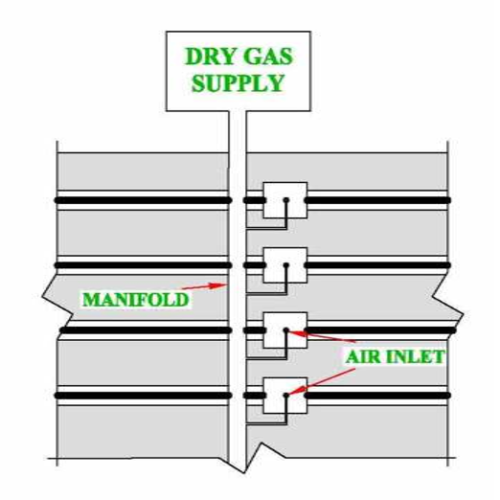

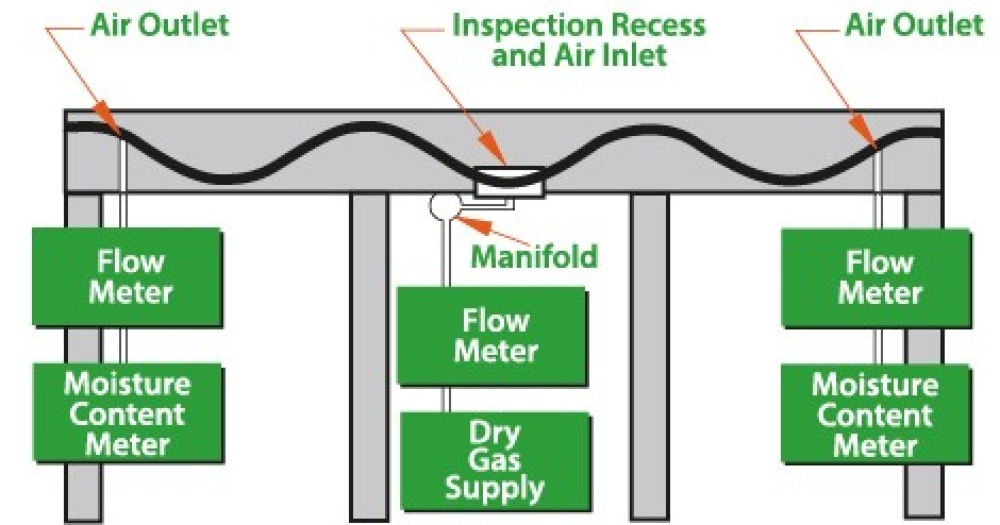

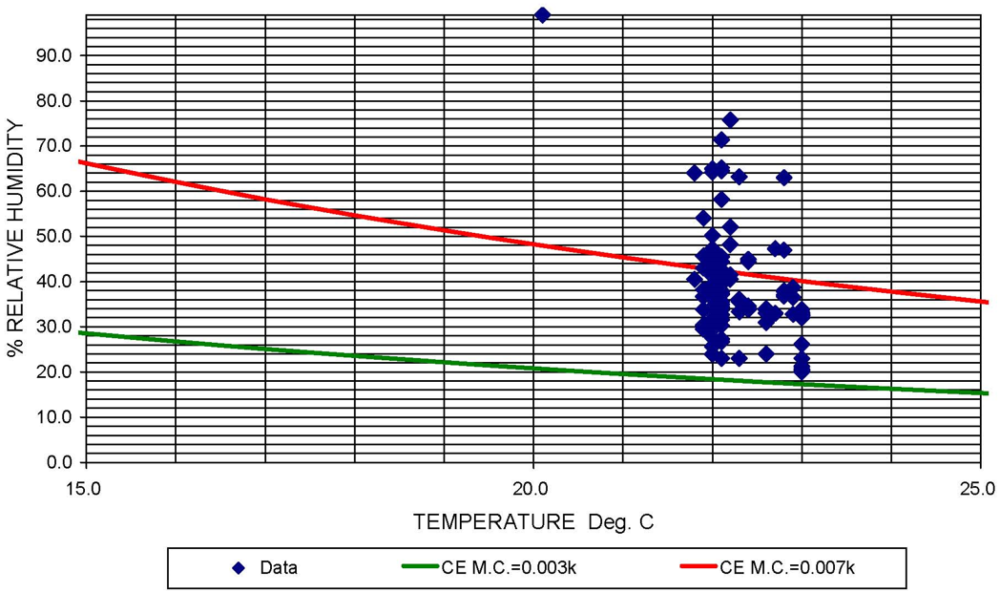

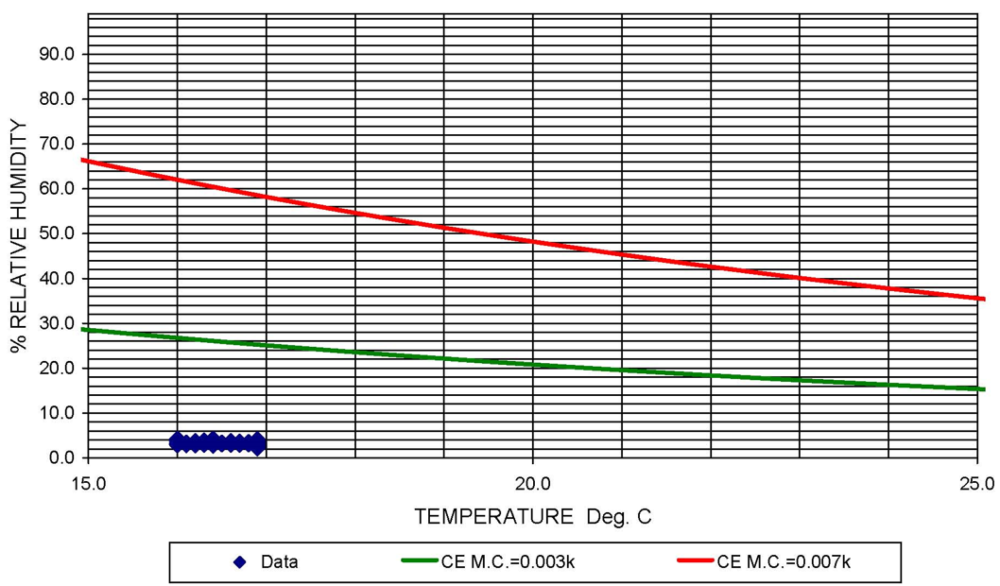

Post-Tech® Cable Drying is an economical corrosion mitigation solution for unbonded post-tensioned cables encased in push-through or heat-sealed sheaths. The process purges moisture from the cable by cyclically pressurizing a dry, non-corrosive gas such as air or nitrogen into the cable sheath. The process continues until the full length of the cable is dry.

Post-Tech® Cable Drying is typically a single treatment that can be adapted for permanent installation when the source of moisture ingress cannot be eliminated. Performance can be monitored manually or by means of electronic sensors installed for remote off-site monitoring and control.

Drying Process

The Post-Tech® Cable Drying system reduces the moisture content inside the cable sheaths by cyclically pressurizing and purging the cables with a manufactured dry gas such as air or nitrogen. The dry gas, which is injected under controlled pressure and flow, causes the existing moisture to exhaust through exit ports, cracks, and defects where moisture may have penetrated. The drying system can use the same ports installed to test the cables when the Post-Tech® Corrosion Evaluation test method is used.

A single Post-Tech® Cable Drying treatment is used for structures where the future ingress of moisture is unlikely, such as interior slabs of fully enclosed office buildings. A single treatment is also suitable when used in conjunction with the Post-Tech® Grease Injection system of re-packing cables or if the application of a membrane has eliminated the source of moisture intrusion.

A permanent cable drying system incorporates a dry gas manufacturing plant, gas distribution lines to all identified cables in a structure and utilizes control and testing equipment to ensure specified levels of protection. Performance can be monitored manually or by means of electronic sensors installed for remote off-site monitoring and control.

After the drying process is complete, the potential for future corrosion is significantly reduced.

Post-Tech® Grease Injection

Corrosion of unbonded post-tensioned cables in heat sealed or push-through cables can be attributed to one or a combination of these causes:

- Poor quality grease

- Inadequate or “spotty” grease coverage

- Air voids in the sheaths

- Inadequate protection at anchor zones

- Damaged or exposed sheaths

- Exposure to environmental elements prior to installation

The Post-Tech® Grease Injection system can address all of these conditions by using a proven method of re-packing post-tensioned cables. Grease has been shown to fill the cable voids and to penetrate cracks, defects and porous grout plugs through which moisture can otherwise penetrate. The re-packing of unbonded post-tensioned cables with corrosion-inhibiting grease provides a cost-effective way to prevent or minimize further deterioration. It is recommended that the system be used in conjunction with the Post-Tech® Cable Drying system to assure that all moisture is purged from the cable sheath.

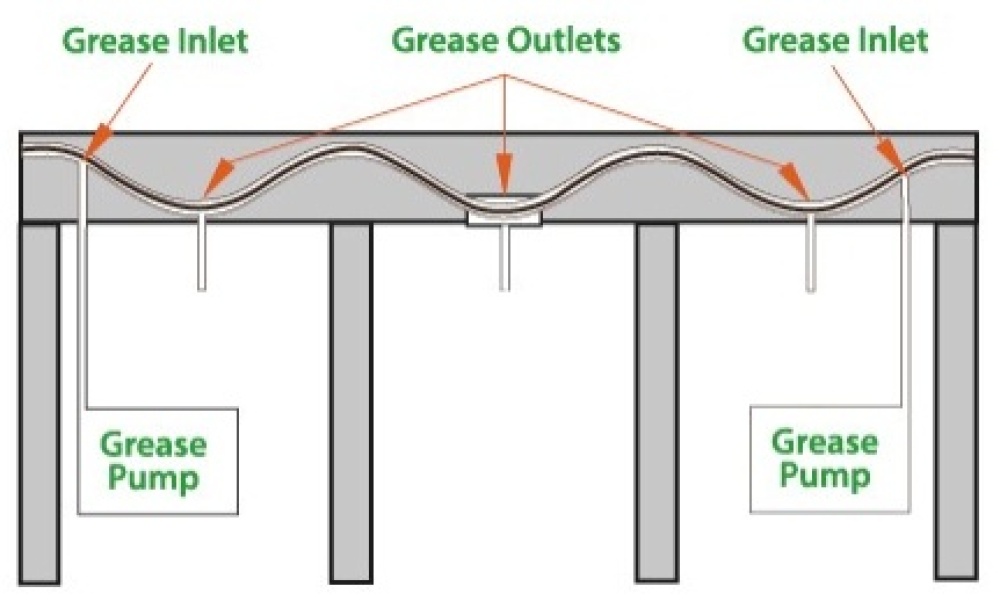

Grease Injection Process

After moisture inside each cable sheath is expelled with the Post-Tech® Cable Drying process, rust-inhibiting, Post-Tensioning Institute (PTI) specified grease is injected under pressure through installed ports or exposed cable anchors to ensure full coverage. The grease fills the sheathing over the entire length of cable greatly reducing or eliminating air pockets. The grease typically provides good penetration into the anchors and grout plugs and helps to seal the joint between the grout and the concrete.

Post-Tech® Grease Injection can provide complete coverage of every wire of the cable and is a proven system that reduces the risk of future cable corrosion.

The Post-Tech® Grease Injection process is used in conjunction with Post-Tech® Corrosion Evaluation, and Post-Tech® Cable Drying to provide an economical solution for engineers and building owners to address their corrosion mitigation and protection issues. These two systems working together can help extend the service life and integrity of post-tensioned structures at a fraction of the cost of other repair methods.

Applications

- Unbonded post-tensioned slabs or beams in parking structures

- Unbonded post-tensioned building slabs

Technical Documents

Select a document to download product information. For CAD drawings in DWG format please Contact Us.

Technical Data Sheet

Market Segments

This product has been used to solve corrosion problems across these markets.