A Better Way to Build: Sustainability Through Preservation

It’s no secret that the concrete industry significantly impacts our world and society. Concret…

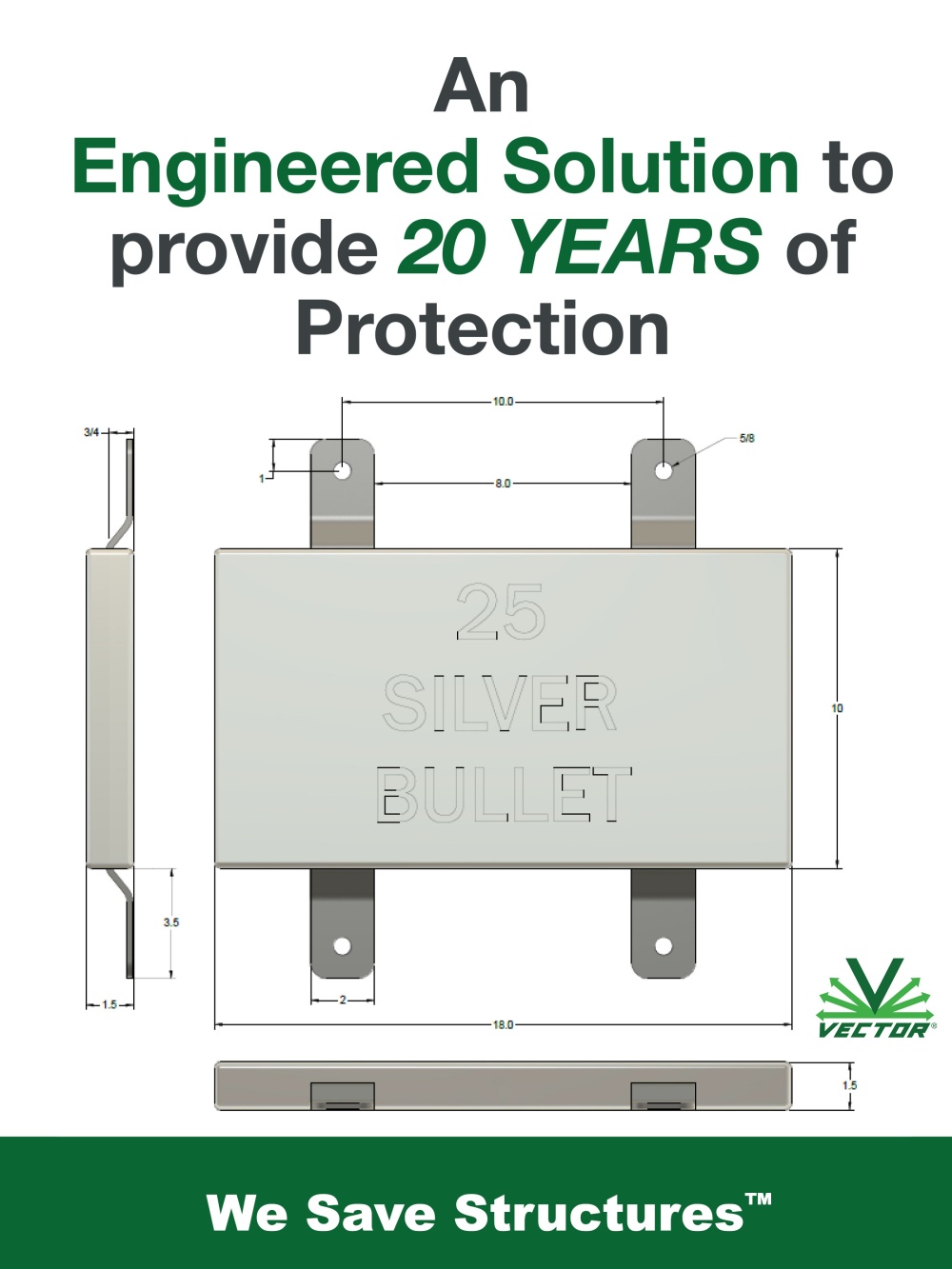

Vector’s Silver Bullet® Al Anode has been specifically designed for use with Vector’s Galvashield® Jacket Systems for concrete and steel piles. The 25 lb. (11.3 kg) mil-spec aluminum alloy will provide over 20 years of protection to most concrete and steel piles without contributing to marine life zinc toxicity.

When galvanic cathodic protection pile jackets were introduced in the 1990s, they utilized an off-the-shelf standard bulk zinc 48 lb. (21.8kg) hull anode designed to protect marine vessels.

Over 20 years later, Vector offers a fresh look at optimizing the performance of submerged anodes with reduced environmental impact. Our approach starts with a cathodic protection system design that recognizes that not all piles are the same and ends with an improved option to standard bulk zinc hull anodes.

Galvanic protection for concrete piles starts from the bottom up, and an undersized bulk anode system will shortchange your galvanic protection investment.

The total surface area of steel to be protected by the anode is a function of the reinforcement pattern, concrete cover thickness, concrete resistivity, pile size, and submerged length. Larger and longer piles will require more anode mass to achieve the designed service life.

An underappreciated and frequently overlooked step is to determine if pile-to-pile continuity exists. If pile steel is tied to or touches the pile cap steel, individual piles will be electrically continuous with each other. This factor must be accounted for in the design of the cathodic protection system.

After the physical parameters of the piles are determined, an understanding of water salinity is essential to ensure proper anode alloy selection.

The type of anode alloy and mass required for the intended service life must be determined. Vector recommends that the anodes be sized to achieve a minimum 20-year service life at a current density of 0.5 to 1.0 mA/ft2 (5 to 10 mA/m2), but these design parameters can be adjusted.

It’s no secret that the concrete industry significantly impacts our world and society. Concret…

WINNIPEG, MB, April 21, 2025 — Vector Corrosion Technologies (VCT) today announced that it has acq…

Reinforced concrete forms the backbone of our modern world. Yet, the very element that strengthens i…