A Better Way to Build: Sustainability Through Preservation

It’s no secret that the concrete industry significantly impacts our world and society. Concret…

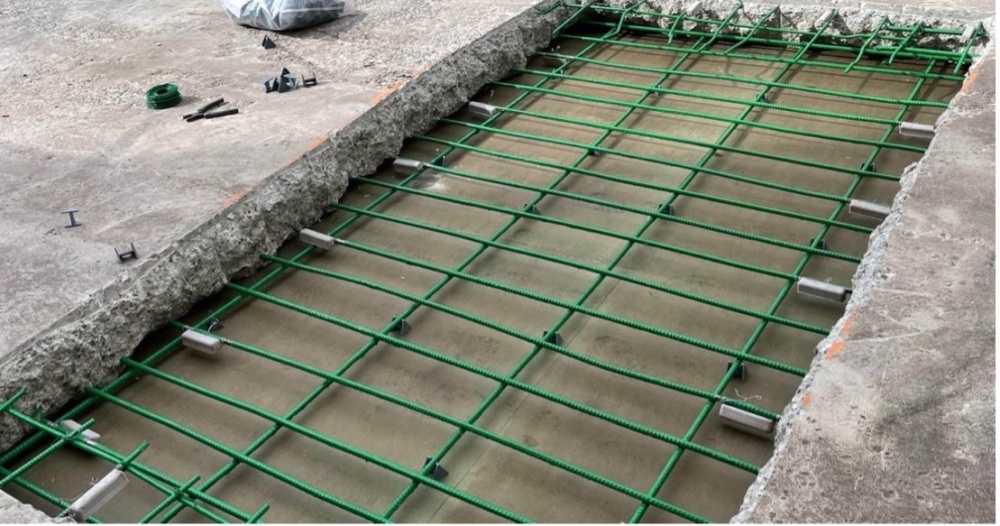

Reinforced concrete forms the backbone of our modern world. Yet, the very element that strengthens it, steel reinforcement, also introduces the risk of corrosion. This silent adversary leads to concrete spalling, delamination, and ultimately, structural failure. At Vector Corrosion Technologies, we understand the critical importance of safeguarding these vital assets. Let's delve into the advanced strategies that can combat concrete corrosion and extend the lifespan of your infrastructure.

Corrosion isn't a singular event; it's a complex process that can be driven by multiple factors:

Get a deeper understanding of the science of corrosion here.

While traditional methods like surface-applied membranes offer some protection, structures that are already corroding and need long-term solutions require advanced technologies:

Initially built in the '60s and expanded to accommodate heavier use over time, many of the tunnels retained original sections, which were tied into the newer concrete repairs. This, combined with exposure to atmospheric saltwater, made for a highly corrosive environment.

Vector Corrosion Technologies' Galvashield® XP4, CC, Fusion® T2, and SM-DAS anodes were deployed during the repairs to protect the tunnels from future corrosion. This project demonstrates the effectiveness of combining multiple CP technologies. You can read the entire project profile here.

Decades of freeze-thaw cycles and application of de-icing chemicals lead to severe corrosion on this reinforced concrete bridge. It required significant rehab to improve the structure's safety while also ensuring it was protected and preserved because of its historical significance.

ECE and Galvashield® XP anodes were used to address chloride-induced corrosion and preserve the bridge's historical integrity. Read the complete project profile here.

Surveys on the bridge revealed significant deterioration on the bridge deck, cap beams, arch ribs, and pier bases due to chlorides and freeze-thaw conditions. Galvashield® DAS, XP4, and Fusion® T2 anodes, along with activated arc spray zinc (ASZ) were implemented to help MNDOT achieve their goal of extending the service life of the Third Avenue Bridge by another 50 years.

Read the project profile here.

Vector Corrosion Technologies is at the forefront of concrete corrosion mitigation, continuously innovating to provide sustainable and effective solutions. We continue to advance the development and implementation of advanced technologies to extend the life of infrastructure.

If you're facing corrosion issues in your concrete structures, our corrosion specialists can help identify the most effective approach. Whether you're looking for short-term protection or long-term corrosion mitigation strategies like cathodic protection, our experts can guide you in addressing your challenges. Contact us today to discuss how we can help protect and preserve your valuable infrastructure.

Learn more about how to preserve concrete structures for future generations here.

It’s no secret that the concrete industry significantly impacts our world and society. Concret…

WINNIPEG, MB, April 21, 2025 — Vector Corrosion Technologies (VCT) today announced that it has acq…

World of Concrete Announces the 2025 Innovative Product Award Winners : The third annual awards …