Why Does Corrosion Happen?

Understanding Corrosion of Steel in Concrete Structures

Welcome to Vector Corrosion Technologies' deep dive into the fascinating and often misunderstood world of corrosion. In this blog, we'll explore why the corrosion of steel in concrete structures is a significant issue, how it occurs, and what can be done to mitigate its effects. Whether you're a civil engineer, a construction professional, or simply curious about the science behind corrosion, this article is for you.

What is Corrosion?

Corrosion is a natural process where metals deteriorate due to reactions with their environment. This is the result of chemical and electrochemical reactions. Concrete corrosion often refers to the deterioration and more specifically the corrosion of the steel reinforcement within the concrete.

The Electrochemical Reaction

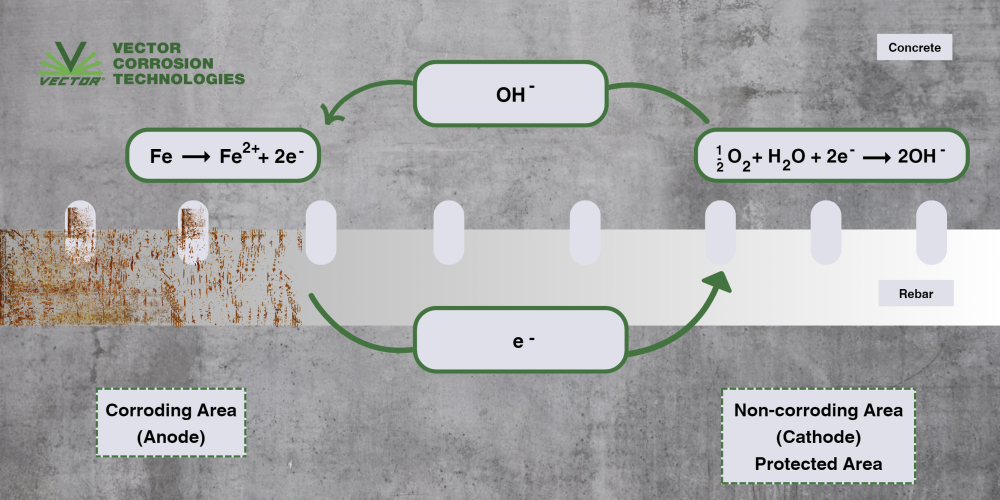

Corrosion is an electrochemical reaction, meaning that the reaction includes both electrical and chemical reactions (Figure 1):

- Anode: The site where the metal section is lost, and rust is formed. This section loses electrons to the cathode in the process.

- Cathode: The site where no corrosion or section loss occurs. This section receives electrons from the anode.

To learn more about concrete durability, watch this YouTube video.

Why Does Steel in Concrete Corrode?

Steel embedded in concrete forms a passive oxide film due to the high pH of the concrete. This high pH environment promotes the creation of a stable, tightly adhered oxide layer that acts as a protective barrier for the steel.

Steel can corrode when solid concrete is contaminated with corrosive compounds or is exposed to reactive liquids and gases. When this occurs, corrosion can initiate.

When steel is embedded in concrete, it develops a passive oxide film due to the high pH of the concrete. The high pH creates an environment that promotes the formation of the passive film, which is basically stable, tightly adhered rust. and acts as a protective layer.

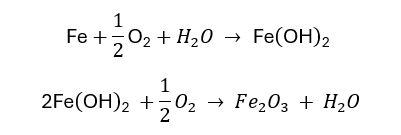

- Steel: Iron (Fe) in the steel rebar reacts with oxygen (O2) and water (H2O) in the concrete to initially form and eventually reacts to form common red rust (Fe2O3) and other corrosion products.

- Chlorides: Chlorides from de-icing salts or marine environments can also penetrate the concrete, break down the protective layer, and initiate corrosion of the steel rebar.

Damage Resulting from Corrosion:

Steel’s natural tendency to corrode and revert to its original, lowest-energy state in the form of iron oxides can result in damage to concrete structures. The expansive byproduct of the corrosion process (formation of rust) causes tensile stress in the concrete cover leading to concrete cracking, delamination, and spalling.

What Causes Corrosion of Steel in Concrete?

Primary causes of corrosion:

- Exposure to saltwater or de-icing salts: These corrosive substances can penetrate the concrete and initiate corrosion of the reinforcing steel over time.

- Carbonation: Carbon dioxide from the air reacts with calcium hydroxide in concrete, reducing its pH and leading to rebar corrosion.

There are other mechanisms that can degrade concrete such as microbes, chemicals, and industrial waste.

What Can We Do to Mitigate/Prevent Corrosion?

Cathodic Protection:

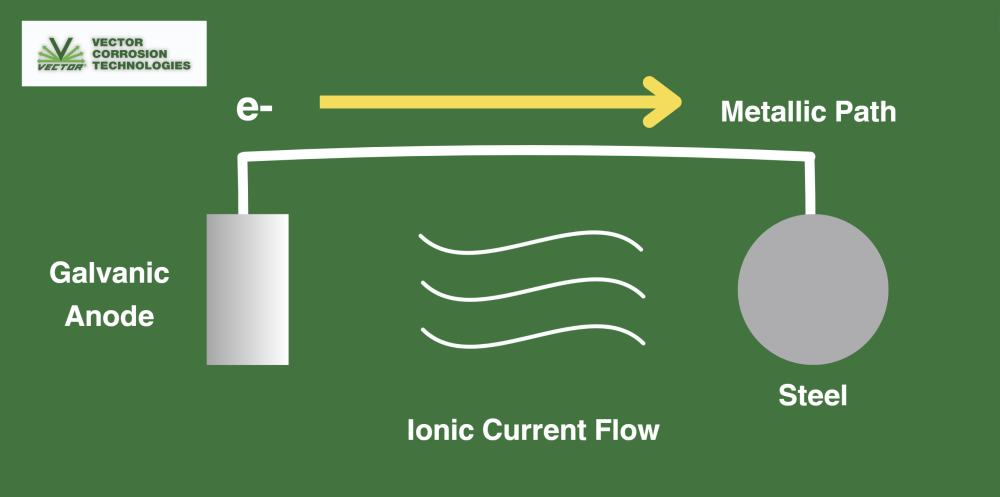

Cathodic protection (CP) is a method of corrosion control that applies a direct current to a metal under protection, forcing it to become a cathode (Figure 2).

Two Types of Cathodic Protection:

Cathodic Protection (CP) is a method of corrosion control, involving the application of direct current to the protected metal, forcing it to become a cathode.

- Galvanic CP: prevents corrosion by connecting a more reactive metal, like zinc, to the steel reinforcement (rebar), causing the more reactive metal to corrode instead of the steel. This process transfers electrons from the anode to the steel, protecting the steel from corrosion and deterioration.

- Impressed Current CP: Uses an external power source to apply a direct current to the steel reinforcement, making it the cathode, and preventing corrosion. This method allows for precise control of the protective current, ensuring effective long-term protection against corrosion.

- Electrochemical treatments, such as chloride extraction and realkalization, are similar to impressed current methods. However, these treatments are temporarily applied to address the underlying cause of corrosion. Once the treatment is completed, the concrete is left in a passive condition.

Explore our range of cathodic protection systems here.

Watch to learn why it’s important to Not Patch it but Repair It.

Environmental Impact of Corrosion

Corrosion affects concrete structures globally, resulting in annual costs in the billions.

Steel corrosion in concrete is accelerated in severe conditions, particularly those with high salt levels or extreme temperatures.

Steel production accounts for 27% of worldwide manufacturing carbon dioxide emissions and 10.5% of total global carbon dioxide emissions. Replacement of corroded steel accounts for 1.6–3.4% of all CO2 emissions.

Are you weighing your options between a rebuild or a repair? Check out our Environmental Impact Calculator to understand the effects your project has on our environment.

The Full Cost of Corrosion

Reinforcing steel corrosion is the primary cause of concrete deterioration and if this process is not understood and addressed, the structure will deteriorate unnecessarily and may be considered for replacement. “It is important to consider the total cost of each option before making a decision. Decisions are often made based on initial cost or construction cost and do not include the full societal cost which includes the cost of delays, congestion, and environmental costs. Informed decisions should be based on full costs.” (Dave Whitmore)

Conclusion

Corrosion of steel in concrete is a widespread issue with far-reaching effects on infrastructure, the environment, and the economy. Understanding the underlying causes, such as chloride infiltration and carbonation, is crucial for developing effective prevention and mitigation strategies.

Implementing solutions like embedded galvanic anodes or impressed current systems can significantly reduce the rate of corrosion of steel in concrete. Adopting high-quality materials, adhering to proper construction practices, and conducting regular inspections are all essential to avoid the detrimental effects of corrosion.

By proactively addressing corrosion, we can enhance the durability and safety of our infrastructure, protect the environment, and reduce economic costs. Ensuring our structures remain robust and resilient is not just an engineering challenge but a societal necessity.

For more insights and detailed solutions to combat corrosion, stay tuned to our blog and ensure your structures stand the test of time.