Galvashield® Fusion® T2

Fusion Technology

Self-powered two-stage anode for proactive protection of reinforced concrete structures.

Want to see some of the research we used to develop our Galvashield® Fusion® product line?

The following paper titled: A Two-Stage Cathodic Protection System Combining ICCP Components with Long-Term Galvanic Anode Steel Reinforcement Protection was presented by our team at the AMPP Annual Expo and introduces the concept and principles of the technique, illustrates products developed and presents medium-term field studies to demonstrate the success of the Two-Stage CP technique.

Click below to download the full paper:

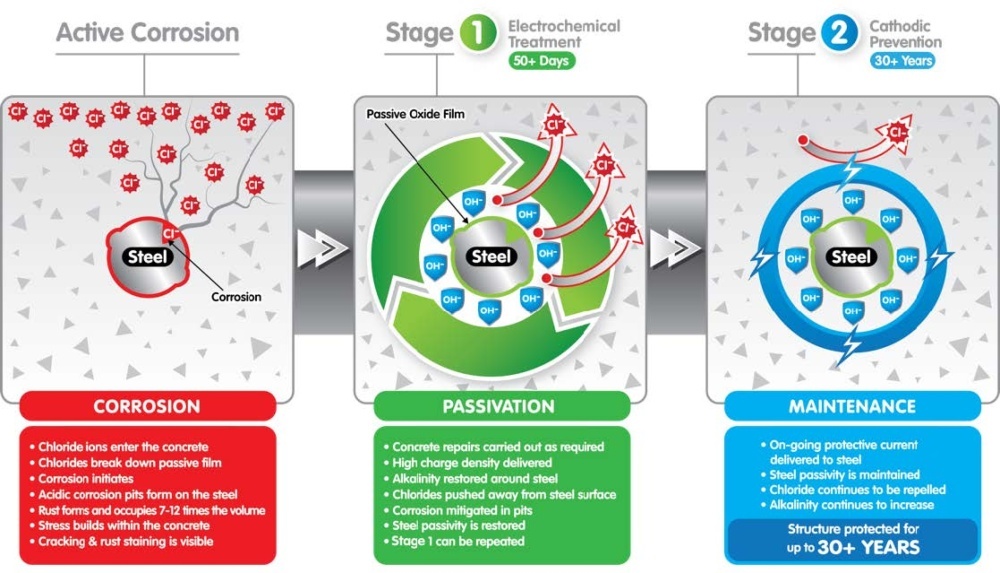

There is no doubt that Impressed Current Cathodic Protection (ICCP) of steel reinforced concrete has, over the last decades, become a well-established technique for controlling reinforcement corrosion of structural elements. The expectation of long-life protection has, however, been somewhat reduced as some anode systems fail, monitoring equipment becomes antiquated, and lack of adequate maintenance makes the systems inoperable, with the average service life of any ICCP system falling to 15-20 years. Inevitable additional costs are involved in maintaining and prolonging the correct operation of the system.

It appears that there is a requirement by structure managers and owners for simpler cathodic protection (CP) systems which will involve less maintenance and monitoring requirements.

Galvanic anode systems are another tried and true solution for protecting reinforced concrete from corrosion. These systems generally require little to no maintenance or monitoring and, often at a lower cost, can seem like the perfect solution.

Unlike an ICCP system, however, their main limitation is the level of current they can provide and their potentially shorter service life.

Existing standards like ISO EN 12696:2022 and NACE SP0290-2017 have clear performance criteria that need to be satisfied to ensure that a cathodic protection system is working. These require a set level of protection for the entire life of the system.

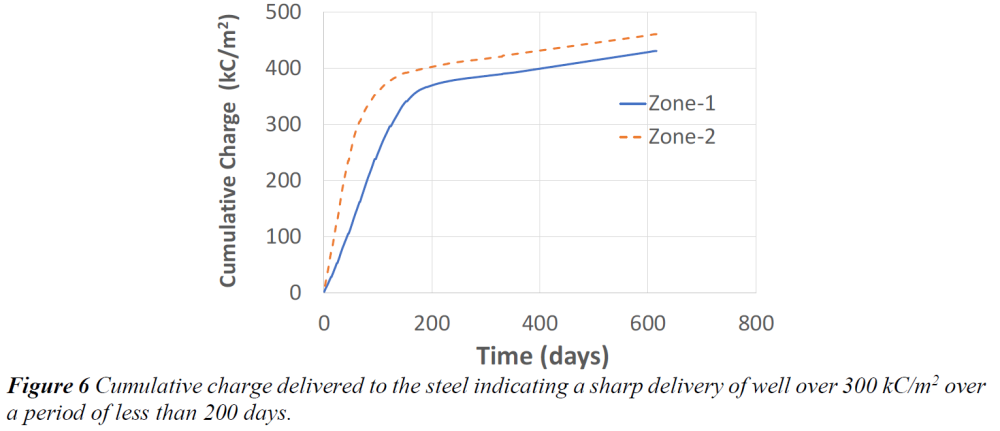

What this paper shows is that the current density and overall charge delivered can lower the requirement for successful corrosion arrest of the steel reinforcement.

Laboratory experiments established that corrosion of steel reinforcement can be arrested within relatively short periods if a sufficient cathodic current density higher than 20 mA/m2 is applied.

After corrosion is arrested, it is only necessary to maintain steel passivity longer-term by cathodic prevention, a process that requires a much-reduced current density.

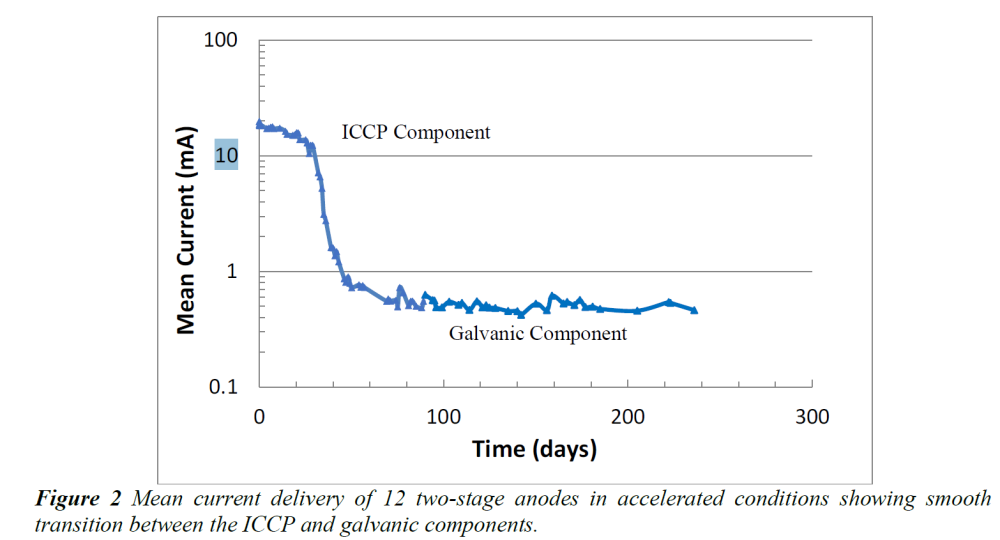

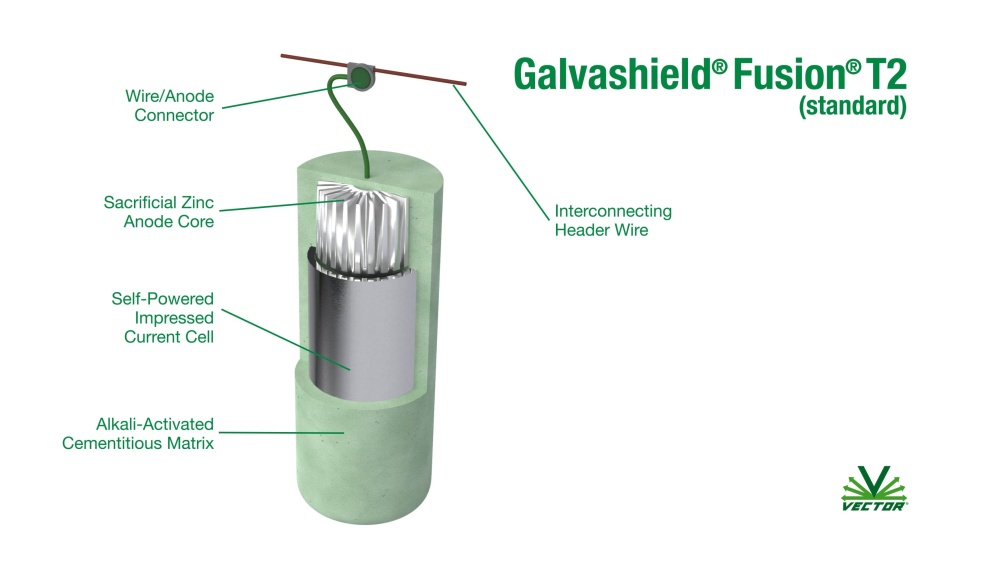

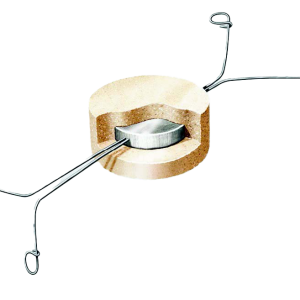

Once the two-stage principle was tested and established in the laboratory, self-contained anodes were developed, each product comprising a battery-operated Impressed Current Cathodic Protection element and a galvanic anode component.

A high initial current output substantially above 20 mA/m2 by area of steel is delivered over a period of weeks during which corrosion arrest is achieved. The galvanic anode components then deliver the lower cathodic prevention current long-term.

By integrating the ICCP and Galvanic systems into one unit, this two-staged system front loads a higher current to arrest corrosion and then automatically switches to a lower output maintenance stage that confidently ensures the passivity of the steel for decades to come.

Learn more about Galvashield Fusion on our technology page:

Our Nick Drews, Business Development Manager for the Mid-West United States region, has been awarded…

This paper was recently featured in Materials Performance Magazine. You can check out that version o…

25 Years of Galvashield : A Walk Through Our Innovation Milestones : 1999 : Launch of the Galvashi…